Fill your vehicle with a smarter fuel.

Natural gas is a plentiful, clean, and low-cost alternative to diesel and gasoline with an established, reliable refueling infrastructure coast-to-coast. And fueling with RNG can achieve a carbon-negative fleet outcome depending on its source

Find a natural gas station

Use our interactive map to find CNG and LNG stations near you. This unique tool also includes the incremental driving range that each station supports.

WHAT IS HYDROGEN?

Hydrogen is the simplest, most abundant element in the universe

Naturally occurring hydrogen — often called geologic hydrogen — exists trapped beneath Earth’s surface. But as a colorless, odorless, and tasteless gas that is 15 times lighter than air, hydrogen can be difficult to find and harness in nature.

PURE POWER

What is natural gas?

What is natural gas?

Plentiful fuel source

Natural gas is a naturally-occurring, plentiful, odorless substance composed mainly of methane, a compound with one carbon atom and four hydrogen atoms. Natural gas also contains small amounts of hydrocarbon gas liquids and nonhydrocarbon gases. By comparison, gasoline has eight carbon atoms while diesel has sixteen. And unlike gasoline and diesel that are refined from crude petroleum – expending additional energy and creating added emissions – natural gas is not refined before its use as a clean transportation fuel.

Smart alternative

Because natural gas is abundant, cost-effective, and clean, it is a smart, low-emission alternative to traditional transportation fuels like gasoline and diesel. With an octane rating of approximately 130, natural gas allows for increased engine compression and combustion efficiency in vehicles and nonmobile sources in which it operates.

TYPES OF NATURAL GAS

TYPES OF NATURAL GAS FUEL

CNG or LNG?

Compressed vs.

liquefied

CNG (Compressed Natural Gas) and LNG (Liquefied Natural Gas) are both captured from recoverable and renewable sources. The difference is in the way they are stored and transported.

CNG (Compressed Natural Gas) and LNG (Liquefied Natural Gas) only differ in the way they are stored and transported.

CNG

Production – Compressed natural gas, or CNG, is natural gas stored and transported under high pressure in its gaseous form, making it lighter than air. CNG is produced by compressing natural gas to less than 1 percent of its volume at standard atmospheric pressure. CNG is safer than gasoline and diesel because it is nontoxic and disperses quickly.

Transportation – After exiting the ground or extracted from a biodigester, natural gas is transported by pipeline or by virtual pipeline via tanker truck where it is compressed and stored at 3,600 pounds per square inch (PSI).

Delivery – CNG is transferred from storage to a CNG vehicle through a fill nozzle and receptacle.

LNG

Production – Liquefied natural gas, or LNG, is natural gas stored and transported as a liquid. After being sourced from the ground or from methane-producing waste products, LNG is produced by purifying natural gas and super-cooling it to -260 degrees Fahrenheit through a process called cryogenic liquefaction.

Transportation – LNG is transported via insulated truck, rail, or ship to LNG stations for distribution as a transportation fuel. Because of its greater fuel density and lower weight storage, LNG is an ideal fuel for high horsepower and long-distance transportation needs since it requires fewer tanks and space requirements.

Delivery – Like CNG, LNG can be dispensed through a fill nozzle and receptacle for on-road applications.

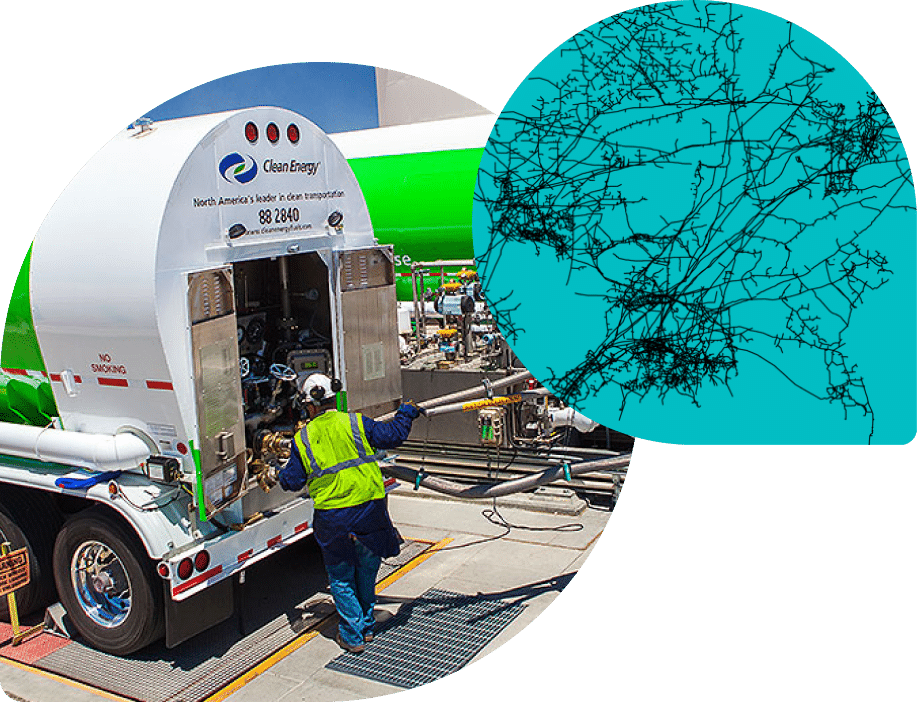

Transporting

natural gas fuel

By pipeline

Natural gas is delivered to U.S. customers through a 2.5 million-mile underground pipeline system. This natural gas can then be compressed or liquefied for use as a transportation fuel.

By virtual pipeline

For natural gas customers in areas where there is little or no infrastructure, CNG is transported via trailer in high-capacity, super-lightweight storage tanks. These trailers are filled at major gas pipelines then driven to end use sites for a continual, uninterrupted supply. CNG can also be transported via standard shipping containers and loaded onto a truck, train, or ship. After cooling to -260 degrees Fahrenheit, LNG can also be transported via virtual pipeline. Cryogenic insulation keeps LNG from boiling off overtime and allows for its tanker transport to end users via truck, train, or ship.

NEW STUDY

Virtual Pipelines

Enabling Customer productivity with safe, practical, and low-cost clean energy delivery solutions.

Virtual Pipeline Fact Sheet Webinar

Fuel news